Pushback Pallet Racking

Maximize Storage Space

Discover the benefits of pushback pallet racking and optimize your warehouse storage.

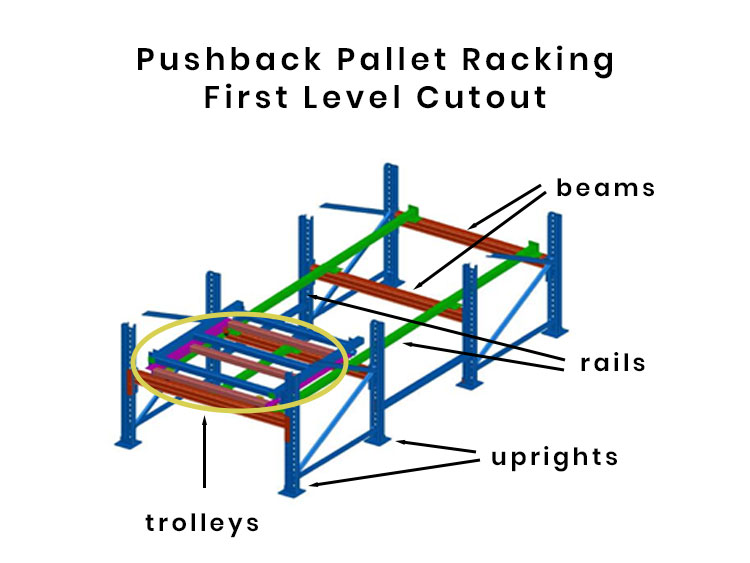

Pushback Pallet Racking Components

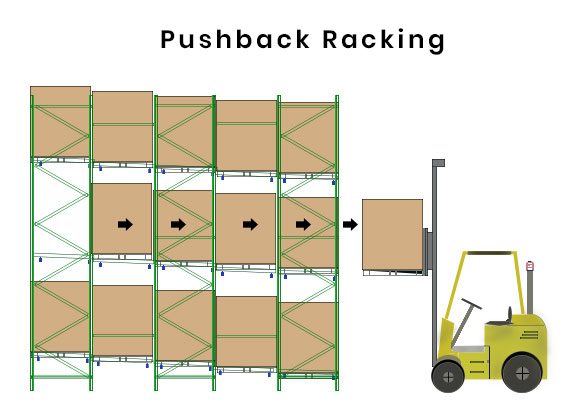

Pushback pallet racking is a high-density storage system ideal for FIFO (first-in, first-out) inventory. It utilizes angled rails and wheeled carts to store multiple pallets deep within a single lane. Pallets are loaded onto carts at the back and then pushed forward as additional pallets are added, making only the front pallet accessible at any given time. This system maximizes storage capacity while still allowing for individual pallet retrieval with a forklift.

Uprights

These are the vertical pillars, typically constructed from high-strength steel, that bear the weight of the entire structure.

Footplates

Pallet racking footplates, also known as baseplates, are metal plates that anchor the upright supports of a pallet rack system to the floor.

Trolleys (or Carts)

Wheeled platforms that sit on the rails, each designed to hold a single pallet.

Rails

Inclined metal tracks that run along the beams, angled to allow pallets to roll by gravity.

Accessories

A vast array of accessories enhances the functionality and safety of pushback pallet racking. Row spacers maintain proper spacing between pallets, while safety bars prevent pallets from accidentally being dislodged. Aisle guard rails protect against forklift damage, and wire mesh back and side panels can be incorporated for additional security and load containment.

Optimize Storage Space with Pushback Pallet Racking

The primary use of pushback pallet racking is to maximize storage density in warehouses. It achieves this by allowing for deep storage of pallets, typically 2-6 pallets per lane on either side of an aisle. This is achieved through a system of slightly inclined rails and carts where pallets are loaded from the front and pushed back on the carts as additional pallets are added.

Benefits

Increases storage density by utilizing the depth of the storage area. Significantly increasing the number of pallets stored compared to traditional pallet racking systems.

LIFO Inventory

Pushback racking is a LIFO (Last In, First Out) system, meaning the last pallet loaded is the first one retrieved.

Innovative and Efficient Pushback Pallet Racking Solutions

Unlock the full potential of your warehouse with pushback racking! This innovative storage solution allows you to store up to 50% more pallets in the same amount of space, freeing up valuable floor space for other income-generating activities. Plus, it excels at efficiently managing LIFO inventory, where the most recently received items are the first ones retrieved. Pushback racking: maximize space, prioritize safety, and optimize LIFO inventory management – all in one powerful solution.

Unlock the Benefits of Pushback Pallet Racking for Efficient Warehouse Storage

The primary use of pushback pallet racking is to store more pallets in a smaller warehouse space. It achieves this through:

Space Efficiency: Pushback racking maximizes storage capacity by storing pallets deep within the racking system, typically 2-6 pallets per lane. This allows you to store more pallets in a smaller footprint compared to selective racking where each pallet gets its own level.

Improved Warehouse Throughput: Since you only need access to the front of the lane to load or unload pallets, there can be faster loading and unloading times, especially for frequently accessed items stored at the front. This can improve overall warehouse throughput for those specific items.

This combination allows warehouses to store a significantly higher volume of goods compared to traditional racking systems, making it ideal for:

Warehouses with limited space: When maximizing storage capacity is crucial due to space constraints, pushback racking offers a significant advantage.

LIFO Inventory Management: Pushback racking operates on a LIFO (Last In, First Out) basis. This means the last pallet loaded is the first one retrieved, which can be a drawback if you need frequent access to older inventory stored deeper within the lanes.

Safety Benefits: Pushback racks eliminate the need for forklifts to enter narrow aisles between racking units, which is a common practice with drive-in racking. This can significantly reduce the risk of accidents and injuries to warehouse personnel.

However, it’s important to consider some drawbacks as well:

Limited Selectivity: Unlike selective racking, you can only access the front pallet in each lane directly. Reaching pallets stored deeper in the lane requires removing the ones in front, which can be time-consuming.

Space Saver

It maximizes storage space by increasing the number of pallets that can be stored in small spaces. This can potentially increase storage capacity by up to 50% compared to traditional pallet racking.

Efficiency

Since you only need access to the front of the lane to load or unload pallets, productivity is increased through faster loading and unloading times.

Cost Savings

Pushback racks squeeze more pallets into your warehouse. This means you get more storage for your buck, potentially saving on extra rental space in the long run. Even though the initial cost might be a bit higher, it can pay off over time.

Pushback Pallet Racking Installation

Pushback rack installation involves assembling the upright frames, then securing them to the floor for stability. Next, rails with a slight incline are slotted into the frames to create lanes for the carts. These carts, which allow pallets to roll back as new ones are added, are then positioned on the rails. Finally, after everything is aligned and secured, the system is ready to maximize your storage space!

Pushback Pallet Racking Pricing, Features, & Options

The final price of a rack system depends on several factors specific to your needs, such as the overall size and weight of the equipment you plan to store, and any local permitting requirements that might apply to your location.

In order to ensure a safe and efficient installation, a proper facility survey is needed to determine the optimal racking configuration.

WDRacks.com can help you navigate this process, including the engineering and permitting aspects, to deliver a customized solution. We even offer financing options and accept trade-ins on existing equipment, making the process truly hassle-free.

Pushback racking is a compelling choice for warehouse managers seeking a space-saving storage solution. It can save you up to 50% on warehouse space, making it a more cost-effective alternative to expanding to new real estate.

Unlock the Power of Pushback Pallet Racking

Discover the versatility and efficiency of pushback pallet racking solutions for your warehouse.