Fishers Pallet Racking

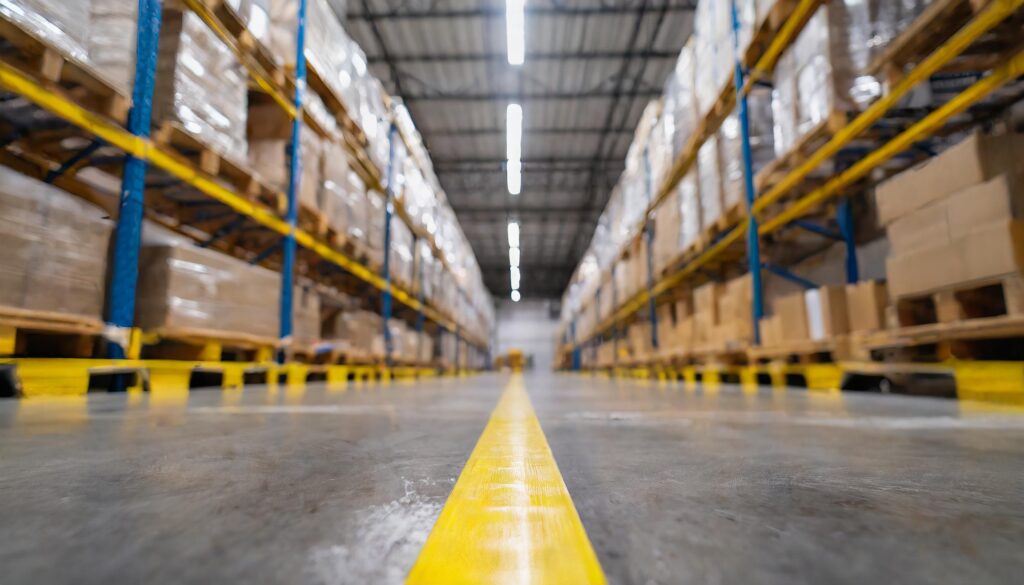

Maximize Warehouse Storage Space

Conquer storage challenges and optimize your warehouse with

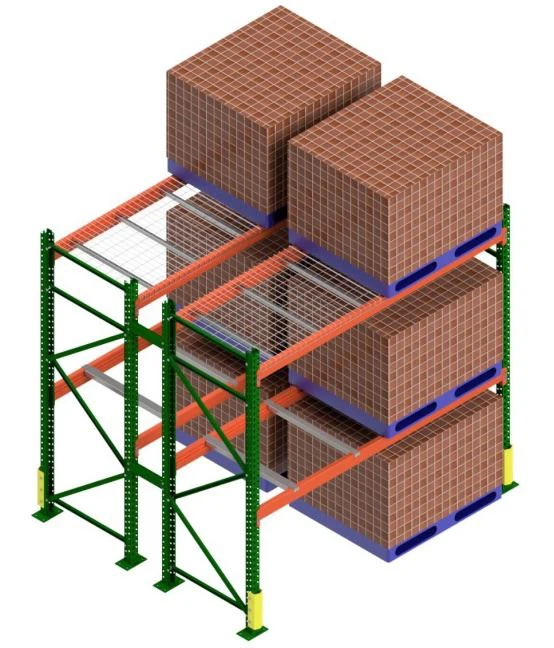

*CITY* Pallet Racking Components

Uprights

These are vertical pillars, typically constructed from high-strength steel, that bead the weight of the entire structure. Uprights come in various heights and weight capacities to cater to specific storage requirements and building limitations.

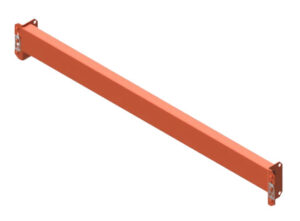

Beams

These are horizontal members also made of sturdy steel, connect to the uprights via slots or clips. Beams provide the platform upon which pallets are placed, and their load capacity determines the maximum weight each level can safely hold.

Footplates

Footplates, metal plates attached to the bottom of pallet rack uprights, are crucial for stability by distributing weight down into the floor and preventing tipping.

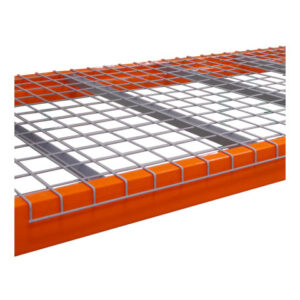

Wire Deck (Optional)

Deck panels can be installed on beams to create a solid surface for storing smaller items or loose boxes. These panels eliminate gaps between pallets, preventing products from falling through.

Accessories

A vast array of accessories enhances the functionality and safety of pallet racking. Row spacers maintain proper spacing between pallets, while safety bars prevent pallets from accidentally being dislodged. Aisle guard rails protect against forklift damage, and wire mesh back and side panels can be incorporated for additional security and load containment.

Boost Productivity and Your Bottom Line with *CITY* Pallet Racking

Benefits

Maximize storage space, easy access to inventory, versatile for different product sizes.

Ease of Installation

Flexible and Adaptable *CITY* Pallet Racking Solutions

Discover the appeal and popularity of

Unlock the Benefits of *CITY* Pallet Racking for Efficient Warehouse Storage

Adaptability and Flexibility

The key feature of

Cost-Effective

Ease to Install and Reconfigure

Compared to other racking systems

Safety and Security

The

Installation

*CITY* Pallet Racking Pricing, Features, & Options

The final price of a server rack system depends on several factors specific to your needs, such as the overall size and weight of the equipment you plan to store, and any local permitting requirements that might apply to your location.

In order to ensure a safe and efficient installation, a proper facility survey is needed to determine the optimal racking configuration.

WDRacks.com can help you navigate this process, including the engineering and permitting aspects, to deliver a customized solution. We even offer financing options and accept trade-ins on existing equipment, making the process truly hassle-free.

Unlock the Power of *CITY* Pallet Racking

Discover the versatility and efficiency of