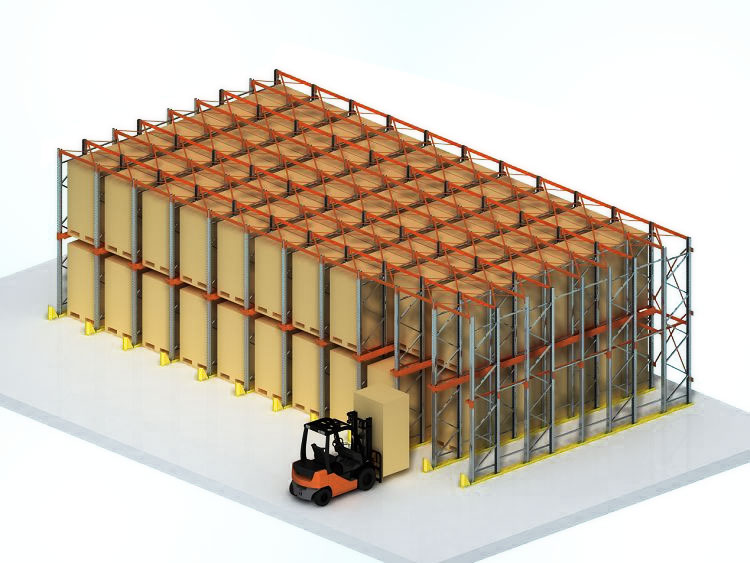

Drive-in Pallet Racking

Maximize Storage Space

Discover the benefits of drive-in pallet racking and optimize your warehouse storage.

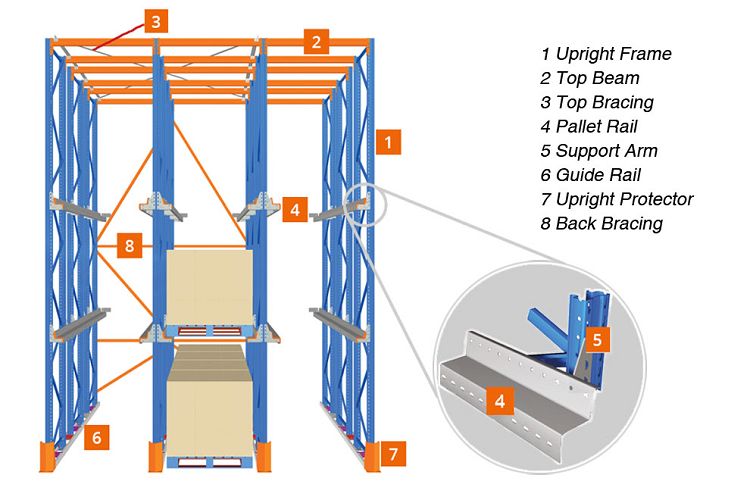

Drive-in Pallet Racking Components

Drive-in pallet racking is a space-saving storage system designed for warehouses with a large quantity of similar items. It utilizes rails and deep lanes within the rack, allowing forklifts to enter and store pallets multiple levels deep.

Uprights

These are the vertical pillars, typically constructed from high-strength steel, that bear the weight of the entire structure.

Footplates

Pallet racking footplates, also known as baseplates, are metal plates that anchor the upright supports of a pallet rack system to the floor.

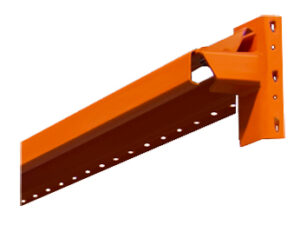

Arm Support

This component is a shorter beam that attaches to the upright and the drive-in rail support beam. It acts as an extension for the upright, providing a secure attachment point for the drive-in rails.

Support Rail

Support rails or "drive-in rails" are attached to uprights and secured to the arm supports. These strong metal components create a ledge that allows pallets to rest on.

Accessories

A vast array of accessories enhances the functionality and safety of drive-in pallet racking. Row spacers maintain proper spacing between pallets, while safety bars prevent pallets from accidentally being dislodged. Aisle guard rails protect against forklift damage, and wire mesh back and side panels can be incorporated for additional security and load containment.

Optimize Storage Space with Drive-in Pallet Racking

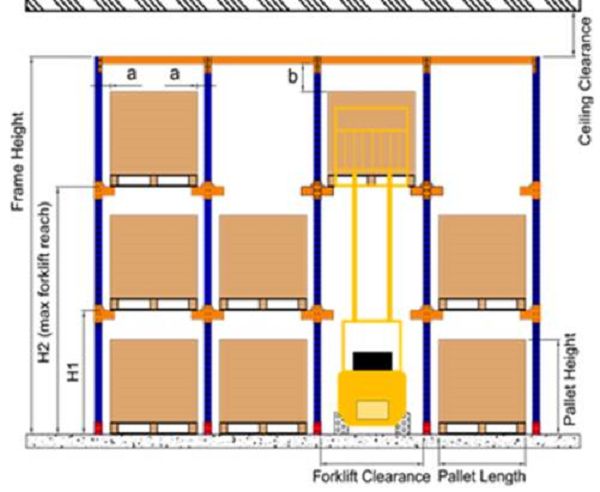

The primary use of drive-in racking is to maximize storage capacity within a warehouse by enabling high-density storage of specific inventory. Drive-in racking allows forklifts to enter the racks themselves, utilizing the space that would otherwise be aisles for additional pallet storage.

Benefits

Maximizes storage space by eliminating wide aisles between racks. This can potentially increase storage capacity by up to 80% compared to traditional pallet racking.

LIFO Inventory

Ideal for storing large quantities of identical or similar items with a low turnover rate. (LIFO – Last-In, First-Out inventory).

Flexible and Adaptable Drive-in Pallet Racking Solutions

Discover the appeal and popularity of drive-in pallet racking, a storage solution that offers unmatched flexibility and adaptability. With its customizable design, drive-in pallet racking allows you to maximize your warehouse space while easily accessing and organizing your inventory.

Unlock the Benefits of Drive-in Pallet Racking for Efficient Warehouse Storage

The primary use of drive-in racking is to maximize storage capacity within a warehouse by enabling high-density storage of specific inventory. It achieves this by:

Eliminating unnecessary aisles: Traditional pallet racking requires wide aisles for forklift maneuvering. Drive-in racking allows forklifts to enter the racks themselves, utilizing the space that would otherwise be aisles for additional pallet storage.

Storing pallets deep within lanes This system allows for multiple pallet levels within each lane, taking advantage of vertical space in the warehouse.

This combination allows warehouses to store a significantly higher volume of goods compared to traditional racking systems, making it ideal for:

Warehouses with limited space: When maximizing storage capacity is crucial due to space constraints, drive-in racking offers a significant advantage.

Large quantities of similar items: Since accessing individual pallets can be cumbersome, it’s best suited for storing a large number of identical or very similar items.

Low-turnover inventory: Drive-in racking is ideal for items that don’t require frequent access (Last-In, First-Out inventory) as retrieving specific pallets might involve moving others in front.

However, it’s important to consider some drawbacks as well:

Safety concerns: Since forklifts operate within the racking system, there’s a higher risk of accidents compared to traditional pallet racking. Proper training and safety protocols are crucial.

Limited accessibility: Retrieving specific pallets, especially those deeper in the lane, can be inconvenient and time-consuming.

Not ideal for all inventory: Drive-in racking isn’t suitable for storing fragile items, perishable goods, or items requiring frequent access.

Space Saver

It maximizes storage space by eliminating wide aisles between racks. Forklifts can enter the racks themselves, allowing pallets to be stored multiple levels deep within each lane. This can potentially increase storage capacity by up to 80% compared to traditional pallet racking.

Efficiency

Since forklifts can access pallets directly within the lanes, retrieval and storing times are often faster. This can improve overall warehouse productivity, especially for frequently accessed items.

Cost Effective

Drive-in racking offers a good storage solution per square foot of warehouse space. While the initial investment might be higher than simpler racking systems, the space savings can lead to significant cost reductions in the long run.

Drive-in Pallet Racking Installation

Drive-in pallet racking maximizes warehouse storage by creating a dense network of lanes accessible by forklifts. Installation involves meticulous planning, from initial weight capacity checks and floor layout to precise assembly of uprights, beams, and drive-in rails. Professional design and installation is recommended.

Drive-in Pallet Racking Pricing, Features, & Options

The final price of a rack system depends on several factors specific to your needs, such as the overall size and weight of the equipment you plan to store, and any local permitting requirements that might apply to your location.

In order to ensure a safe and efficient installation, a proper facility survey is needed to determine the optimal racking configuration.

WDRacks.com can help you navigate this process, including the engineering and permitting aspects, to deliver a customized solution. We even offer financing options and accept trade-ins on existing equipment, making the process truly hassle-free.

Drive-in pallet racking is a compelling choice for businesses seeking a space-saver and cost-effective storage solution.

Unlock the Power of Drive-in Pallet Racking

Discover the versatility and efficiency of drive-in pallet racking solutions for your warehouse.