Anaheim, California is a hub for family fun and excitement in Southern California. Beyond its reputation for world-class theme parks, Anaheim offers a range of attractions. Catch a professional baseball game at Angel Stadium of Anaheim or cheer on the hockey team at the Honda Center. Explore the trendy shops and restaurants of the Anaheim Packing District, a revitalized historic area. Nature lovers can hike or bike through Yorba Regional Park, offering scenic views of the city.

M-F 7:30am-4pm

Related

Pallet Racking Anaheim: Your One-Stop Shop for Warehouse Storage Solutions

Anaheim plays a major role in California’s tourism industry, attracting millions with its world-famous theme park. It’s also a significant contributor to the state’s economy, generating revenue through tourism spending and employing a large workforce. Additionally, Anaheim serves as a cultural hub, offering a unique blend of entertainment options and historical sites.

Anaheim’s business scene extends beyond its famous theme park, boasting a diverse and growing economy:

Tourism Powerhouse: Anaheim is a major tourist destination, generating significant revenue through hospitality, retail, and entertainment spending. Its prime location in Southern California makes it a gateway to a wealth of other attractions. SoCal’s famed beaches are a short drive away, while mountains and deserts offer opportunities for hiking, camping, and outdoor adventures. Los Angeles, with its world-class museums and vibrant nightlife, is easily accessible, making Anaheim the perfect base for exploring all that Southern California has to offer.

Beyond Theme Parks: The city is actively attracting new businesses in various sectors, such as healthcare, manufacturing, and technology, fostering a more balanced economic landscape.

Entrepreneurial Hub: Anaheim fosters a supportive environment for small businesses and startups, with initiatives like the Anaheim Startup Accelerator program providing resources and mentorship.

Growing Population: Anaheim’s population is steadily increasing, creating a larger market for businesses and fueling a demand for new housing and services. This growth presents both opportunities and challenges for the city’s future economic development.

Strategic Location: Anaheim’s proximity to major transportation hubs like Los Angeles International Airport and the Port of Los Angeles facilitates commerce and trade. While not a major logistics center itself, its location strengthens its overall business environment.

Companies seeking to optimize their warehouses with budget-friendly, custom storage solutions that meet safety regulations and avoid costly delays can turn to WDRacks.com for the best pallet racking solutions in the USA.

Optimize Your Warehouse: Explore Anaheim Pallet Racking Solutions from WDRacks.com

PRODUCT OPTIONS

We offer an extensive line of pallet racking solutions to suit any storage requirement, from the most basic selective racking to high-density, space-saving options like mobile racking.

CUSTOM SOLUTIONS

Whether you need a basic setup or a complex, customized solution, our expert engineers will design a system that maximizes your storage capacity and streamlines your workflow.

Selective Pallet Racking: This is the most common type of pallet racking. It provides direct access to every pallet, making it ideal for storing a variety of inventory items. Selective racking is versatile and can be easily adjusted to accommodate different pallet sizes and weights.

Push-Back Racking: This gravity-fed system uses rollers on inclined rails. When you load a new pallet at the back, it pushes the older pallets forward. This system is ideal for FIFO (First-In-First-Out) inventory management.

Drive-In/Drive-Thru Pallet Racking: This high-density storage system eliminates aisles between racks. Forklifts can drive directly into the rack to store and retrieve pallets. It’s best for storing large quantities of identical items with low access requirements. Drive-thru racking has openings on both sides of the rack for a pass-through option, whereas drive-in has a closed back.

Double-Deep Pallet Racking: This type of racking allows you to store two pallets deep per bay, doubling your storage capacity compared to selective racking. To access the rear pallet, you’ll need to remove the front pallet first. It’s ideal for storing slow-moving or identical items.

Carton Flow Racking: Similar to push-back racking, carton flow racking uses rollers to advance cartons. This is ideal for warehouses with high picking volumes.

need more space in your Anaheim Warehouse?

Don’t worry about upfront costs – WDRACKS.COM works with you to secure financing options and even accepts trade-ins for your existing racking.

Pallet Flow Racking: This FIFO system uses gravity-fed rollers to move pallets down a slight incline. Pallets are loaded at the back and roll to the front for picking.

Cantilever Racking: This type of racking is ideal for storing long or odd-shaped items like pipes, lumber, or furniture. It consists of horizontal arms that cantilever (extend outward) from a single upright post.

ASRS or Vertical Carousel Racking: This automated storage and retrieval system (AS/RS) uses a rotating carousel to store and retrieve items. It’s ideal for high-density storage of small, high-pick-volume items.

Mobile: Imagine traditional pallet racking, but instead of fixed aisles between each section, the entire racking unit sits on motorized carriages. These carriages run along floor tracks, allowing you to move the racks electronically with a control panel. With a touch of a button, you can create an aisle only where you need it to access specific pallets.

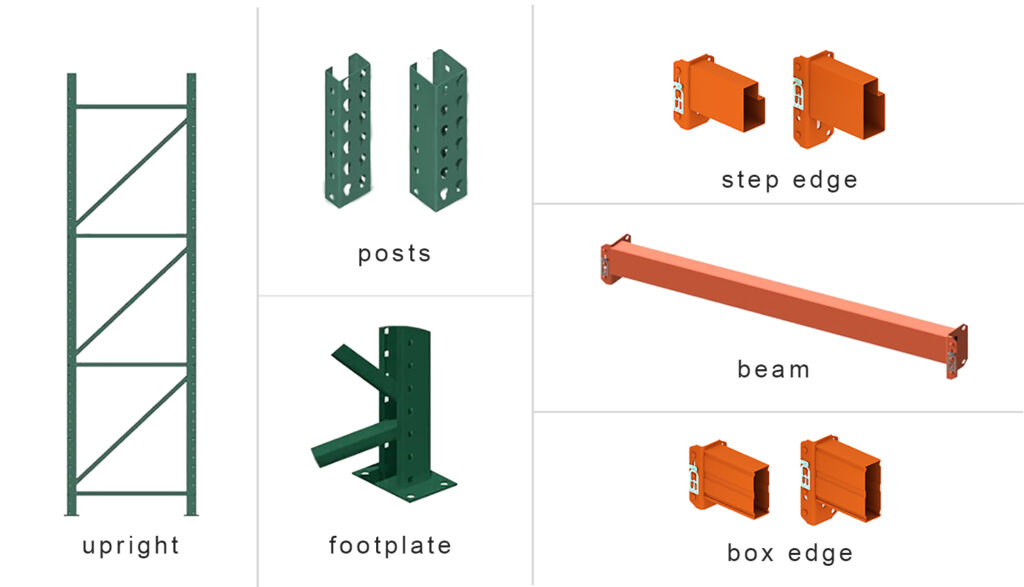

The Nuts and Bolts of Anaheim Pallet Racking Components

Pallet racking systems are the workhorses of warehouses, keeping everything organized and accessible. Here’s a breakdown of the key components:

Upright Frames: These are the sturdy vertical supports, often made of heavy-duty steel. They have punched holes or slots at regular intervals to accept the beams. Uprights come in various heights and weight capacities to suit specific warehouse needs.

Beams: These are the horizontal load-bearing elements that slide into the uprights, creating shelves for the pallets. Beams are available in different lengths and capacities depending on the weight of the palletized goods.

Beam Connectors: These secure the beams to the uprights. They can be clips that snap into place or wedge locks for a more secure fit.

Braces: Diagonal and horizontal braces are welded or bolted to the uprights to provide stability and prevent racking from swaying or collapsing.

Baseplates: These anchor the upright frames to the warehouse floor. They distribute the weight of the loaded racking system and ensure stability. Shims might be used under the baseplates for proper leveling on uneven floors.

Optional Components: Depending on your specific needs, you might incorporate additional elements like:

Wire Mesh Decking: This provides a solid surface on the beams, preventing smaller items from falling through the gaps between pallets.

Row Spacers: These maintain consistent spacing between pallet rack rows for forklift safety and efficient maneuvering.

Safety Bars: These horizontal bars prevent pallets from accidentally being pushed off the back of the racking.

Pallet Supports: These cradles offer additional support for oddly shaped or unstable loads.

Anaheim Pallet Racking Design & Optimization

Easy Process

Let WDRacks.com manage your pallet racking project from start to finish. For over a decade, we've boasted a remarkable success rate, guiding countless warehouses through pallet racking design and optimization.

Budget Friendly

At WDRacks.com, we understand that affordability is key. That's why we offer budget-friendly solutions to fit your needs. We also work with you to secure financing options and even accept trade-ins for your existing racking systems.

Licensed Engineers

All WDRacks.com projects are overseen by a state licensed engineer who reviews plans and calculations to ensure compliance with even the most stringent regulations.

CAD Drawings

Using the latest CAD software, our engineers craft scaled floorplans that satisfy both building and safety departments as well as fire code requirements.

Anaheim Pallet Racking FAQs

Here, we help answer any pre-sales questions you may have about Anaheim pallet racking.

Pallet racking is a storage system specifically designed for warehouses and distribution centers. It uses metal upright frames and horizontal beams to create shelves that can hold heavy, palletized goods. Pallets are flat platforms that products are strapped or wrapped onto, making them easy to move around with forklifts.

The best racking type depends on your specific needs. Consider factors like:

Storage Requirements: How much product do you need to store, and how often will you access it?

Warehouse Layout: What is the available space and ceiling height?

Budget: Consider the upfront cost and potential return on investment.

WDRacks.com offers a free consultation to help you determine the ideal racking system for your Anaheim warehouse.

The maximum height depends on several factors, including:

Warehouse Ceiling Height: This sets the physical limit for racking.

Load Capacity: Higher racks require a sturdier structure to handle the weight.

Building Codes: Local regulations may impose height restrictions.

Yes! WDRacks.com understands that upfront costs can be a concern. We work with you to explore financing options to fit your budget.

WDRacks.com offers high-quality new pallet racking options at a competitive price. We also accept trade-ins for your existing racking systems, helping you save money and upgrade your storage solution.

Yes!, WDRacks.com goes beyond just supplying pallet racking – we're your one-stop shop for a seamless storage solution.

Our team of experts provide comprehensive design services, tailoring a racking system that maximizes your Anaheim warehouse space.

We handle all the engineering calculations, ensuring your chosen system meets safety standards and building codes.

Worried about permits? We'll guide you through the process, taking the hassle out of getting your pallet racking project up and running.

Let WDRacks.com handle everything – from design to permits – so you can focus on what matters most: running your business efficiently.